Electric marine propulsion is your flexible, future-proof choice. Flexibility is a must for your propulsion system because so many things in shipping are uncertain. Flexibility safeguards you from the uncertainty about the availability and cost of sustainable fuels, for example. If you are not sure about the additional power sources that will support your combustion engines, you will need flexibility. And you need it also if you do not know exactly which operational profiles will be sailed.

The classical diesel-electric propulsion systems are so flexible because of their one major advantage. The power generating units (gensets) are only electrically connected to the electric propulsion system. This makes it easier to replace the units with a new power source – such as a future-fuel operated engine, a battery, or a fuel cell.

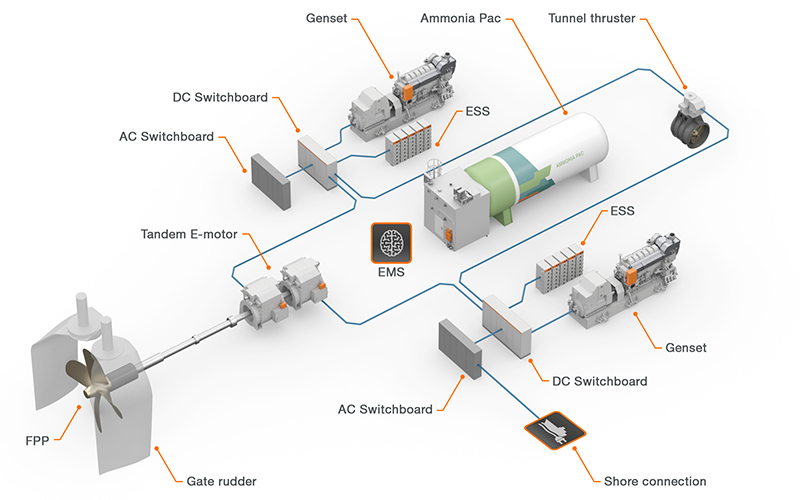

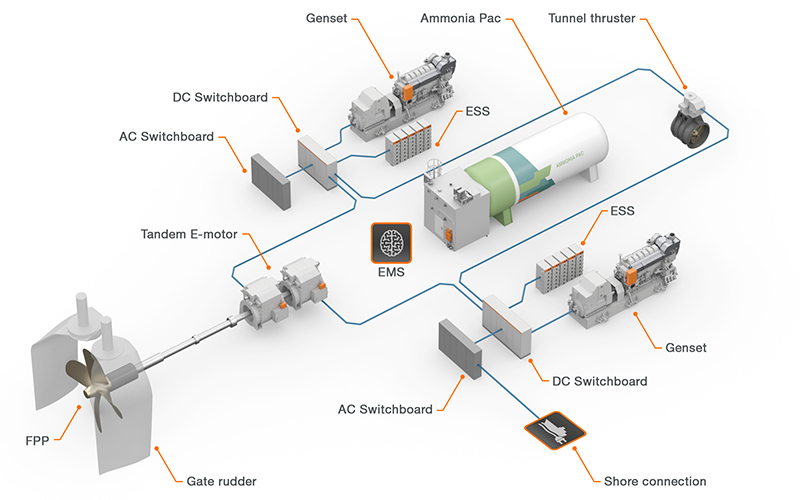

The following is an example configuration of a diesel-electric propulsion system on a vessel:

Diesel-electric propulsion systems continue to be a solid choice for ships that

The current decarbonisation requirements mean that many more types of vessels are considering to adopt electric propulsion.

Wärtsilä has delivered electric propulsion systems to more than 350 vessels – to tugs, offshore vessels, research and special vessels, and to large cruise ships.

The electrical propulsion system is and environment-friendly choice – even with diesel generators. This is because the electrical propulsion system makes it possible to operate the generators within their optimal operational range even when the load from propulsion varies. Therefore, adopting electrical propulsion for a ship will significantly reduce the emissions of NOx/NO, CO, CO2, and soot.

At lower propeller speeds, the number of generators that are online can be adjusted according to the power demand. The engines will run more efficiently, which saves fuel.

Electric propulsion drives are unsurpassed for their quietness of operation.

The propulsion system on the ship can be configured for better redundancy. This makes the system more reliable.

The torque-speed of the motor makes it possible to high-over torque at propeller standstill. The propeller can be driven at all speeds and torques within design limits – there are no other limitations.

The electric propulsion system has excellent dynamic characteristics. Changes in propeller speed and propeller reversals during manoeuvring and positioning can be carried out at optimum acceleration rates.

The electric propulsion system generates only minimal harmonics or voltage drops, which means that the interference to mains is also minimal.

A ship navigation and command system can control the electric propulsion drives automatically, and manually from any control console. The functions and operating states are monitored, which will prevent operating mistakes and overloads.

Choosing an electric propulsion system for a ship instead of a diesel mechanical one means that there are fewer diesel motors and cylinders. The system also allows the motors to operate at constant speed, which reduces wear and tear. The result: lower costs of maintenance and less frequent demand for spare parts, which saves money.