Wire the Fan & Limit Controls on Furnaces

Wire the Fan & Limit Controls on Furnaces Camstat, Cemco, Firestat, Goodman, Honeywell & White Rodgers Fan Limit Controllers

Wire the Fan & Limit Controls on Furnaces

Wire the Fan & Limit Controls on Furnaces This article describes in detail the installation & wiring of furnace combination controls, also commonly called the "fan limit switch" on warm air heating systems.

The photo at the top of this page shows all of the controls and wiring terminals in a Honeywell combination fan and limit control installed horizontally on a gas furnace.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Editor/Publisher - See WHO ARE WE?

Here we include both old and current guides to Installing & Wiring Fan Limit Switches on Warm Air Furnace Heating Systems for all major brands of fan limit control switches used on heating furnaces and other fan systems.

In this article series we also discuss the following:

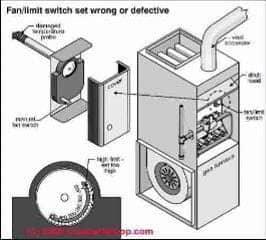

The sketch at above/left, courtesy of Carson Dunlop Associates, shows an improper (too high) upper limit setting - this is an unsafe fan-limit switch setup which is likely to allow the furnace to overheat, risking heat exchanger damage and dangerous carbon monoxide leaks. [Click to enlarge any image]

The following example of wiring a fan limit control switch is based on advice from the Honeywell Tradeline L4064B. Check the test specifications provided by the manufacturer of your particular control.

The switch portion of this Honeywell Fan Limit control can tolerate 190 °F. and the sensing element can handle up to 350 °F.

The control can handle 120V and 240V devices and can also be wired to control low-voltage devices. The electrical wiring used must also be rated for suitable temperature exposure (Honeywell advises wiring rated for 167°F).

At 120V the control can switch fan motor loads at 14 Amps full load (84 Amps locked rotor load), and the limit switch (presumably an oil or gas burner) can handle up to 8 Amps full load (48 Amps locked rotor load).

When controlling 240V devices the fan or blower control can handle up to 7 Amps full load (42 Amps LRA) and the limit switch can handle 4 Amps full load (24A LRA).

This furnace combination control is mounted on the furnace in a location where the bimetallic spring/probe (shown above in this article) will protrude into the warm air plenum to sense furnace air temperatures there. Each furnace manufacturer will provide instructions of where, on their system, the air temperature should be monitored for control purposes.

The reason the control manufacturer warns that the control tip should not touch any internal surfaces of the furnace is that doing so can cause improper reading of furnace air temperatures or could damage the control or prevent free movement of the bimetallic spring in response to temperature changes.

Of course if you are replacing an old control that has failed, just mount the control in the same location that held the prior unit.

When replacing an old furnace limit control, make sure that the new control has a sensing tip of the same length as the unit being replaced. Otherwise the new control may not work safely.

The manufacturer provides details for surface mounting, rigid-bracket mounting, or swivel-mounting of the control. Which of these methods you choose depends on what mounting is needed to place the sensor probe in the proper location in the air plenum.

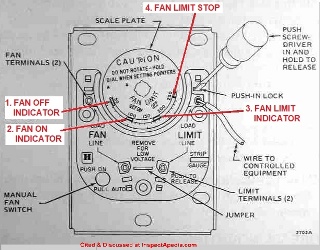

This control can be wired to serve as a safety LIMIT switch on a furnace by wiring just the limit terminals on the control. When the device is used both to control a furnace fan on-and off as well as serve as a LIMIT switch, then all four terminals are used.

Fan control wiring: As Honeywell's illustration shows, the two fan terminals are on the upper and lower left side of the control.

Line voltage is wired at the bottom left push-in terminal.

Load voltage (to the fan) is wired at the upper left push-in terminal.

Limit control wiring: As the illustration shows, the two LIMIT terminals are on the upper and lower right side of the L4064B control.

The Line (power in) wire is connected to the lower right push-in terminal, and the Load (wire to oil or gas burner) is wired to the upper right push-in terminal.

The wiring diagrams shown in more detail below are typical for wiring the furnace combination control on heating systems.

Remember that all electrical wiring of furnace controls (or any other electrical devices) must comply with national and local electrical codes as well as the specifications of the control manufacturer and the furnace manufacturer.

Wires are connected to the control using push-in terminals. A wire strip gauge is provided on the left side of many versions of this control.

The control used for our photos came with additional push-in terminals (Part # 137813) that can be used to convert the push-in wiring connectors to screw-terminal connectors.

This is a great idea if you expect to be changing wiring from time to time. (Dr. Jess Aronstein's research has demonstrated that repeated-use or re-use of push-in type terminals on electrical receptacles does not provide a very reliable connection. This may be true for this control as well.)

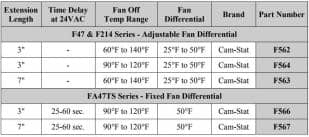

Cam-stat FAL7C-05TD-120-A Fan & LImit control (shown above) [Click to enlarge any image]

Cam-Stat is a division of Supco. The Cam-Stat fan limit switch provides a dial-adjustable FAN OFF temperature ranging from 90°F to 120°F, a FAN LIMIT temperature ranging from 150°F to 250F, and typically a fixed differential of 30°F. [Click to enlarge any image]

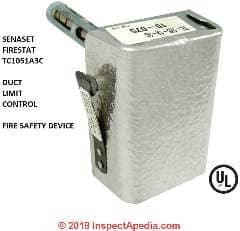

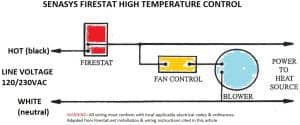

Shown above: the Senasys Firestat HVAC duct fan limit controller, a fire safety device that turns off the HVAC blower in event of a fire.

The Columbus Electric TC Series FIRESTAT is a push-button manual reset limit control designed expressly for fire prevention in warm air ducts.

It may be used with gas, oil, or electric forced warm air heating systems. One or more FIRESTATS should be installed in duct work at critical temperature locations such as down-stream from electric heaters, points where duct work is in close proximity to flammable materials, etc.

FIRESTATS may be used in low voltage or line voltage circuits and are usually wired to open [the] circuit to both heat source and blower when duct air temperature exceeds the temperature setting [of the FIRESTAT safety device].

[Click to enlarge any image]

The TC Duct Limit Controls contain a Helix Bi-Metal that senses rapid increases in duct temperature such as fire. The Bi-Metal causes the normally closed contacts to open and turn off the power

Available in either adjustable [TC-100, TC-105, TC-108] or fixed temperature [TC-205] models. These firestat limit switches are installed in air ducts to shut down heating, air conditioning and ventilation equipment when air temperature in duct exceeds a pre-set limit.

The Duct High Temperature Limits feature a helix bimetal element that senses rapid increases in duct temperature, such as those caused by fire. The high temperature limit then operates an SPST switch that opens with a rise in temperature.

Columbus Electric, originally in Columbus Ohio, U.S. is a division of TPI Corporation. The company produced HVAC controls including fan limit controls such as the unit shown here, line voltage electric heat wall thermostats, and other controls and equipment.

Contact: Columbus Electric Division of TPI, PO Box 4973, Johnson City, TN 37602 USA, Tel 800-251-7828, Fax 423-477-0545

or

TPI Corporation, Website: www.tpicorp.com, Tell: 1-800-682-3398. The company's current product lines include Markel Products, Raywall, and Fostoria and a very large range of HVAC equipment and controls.

Columbus Temperature Control, Columbus Temperature Control, 1053 East 5th Avenue Columbus OH 43201 USA Tel: 614-294-6216 markets under Distech Controls and currently specializes in networked, electronic interfaces and controls for security, HVAC, lighting, access control, energy menagement systems.

Thanks to reader Larry C. for the Columbus Electric Combination Temperature Controller photographs, 2018/07/25. He wrote that this control was used on a dual-zone heating and air conditioning system.

This L4064B, L4064R limit controller is a universal replacement for older furnace fan limit controllers. Here is the difference between the L4064B and L4064R, excerpting from the document above:

These combination warm air fan and limit controllers are suitable for various types of forced air heating systems. The controllers have 2 switches; one which opens the limit circuit if the plenum temperature exceeds the preset safety limit; it resets automatically. The other switch turns the fan on and off.

The fan is turned on and off according to plenum temperature.

The L4064R has a special high temperature range suitable for gravity heating systems.

All models may be used as limit controllers by wiring only the limit side. Limit contacts are suitable for both line voltage and low voltage. For low voltage applications, the brass jumper must be removed.

.

Follow furnace or burner manufacturer’s instructions, if available.

Maximum element temperature is:

L4064B—350 ºF (177 ºC).

L4064R—250 ºF (121 ºC) above limit setting.

L4064 A-F, J, R turn the blower fan on/off based on plenum temperature

L4064 T, W, Y have a 20-90 second delay before turning the fan ON after a thermostat call for heat (avoiding blowing cool air on occupants)

L4064 B,D,F,R,W have also a manual FAN-ON switch to keep the an on continuously

L4064 J,R had a special high-temperature range for older furnaces burning gas, oil, coal, wood

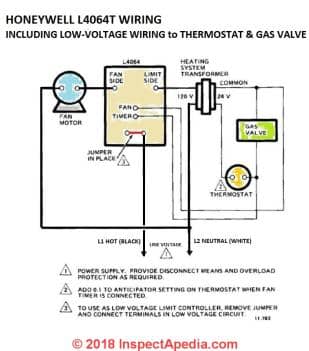

Above: Honeywell L4046T Wiring diagram.

[Click to enlarge any image]

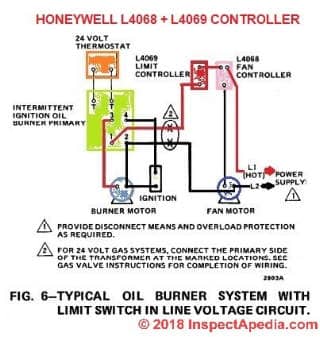

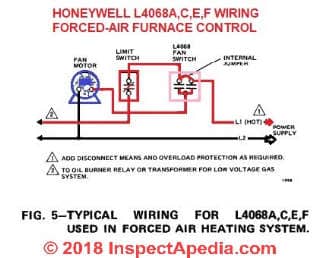

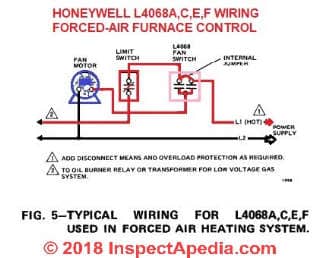

Below: Honeywell L4068A-C-E-F Wiring Diagrams from the manual given just below.

In most applications in the U.S. and Canada the Honeywell L4064B combination control is used to switch on and off 115V-120V or 240V fans and heating burners, or on some gas equipment, the burner controls (the LIMIT switch function) operates at low voltage.

The pull-out or break-off tab discussed below at HONEYWELL L4064B LIMIT WIRING WHEN CONTROLLING LOW VOLTAGE is left in place for line voltage applications.

[Click to enlarge any image]

The left-illustration shows normal wiring for this set-up. The fan or furnace blower motor is controlled by the two left connections (green dots); the furnace limit switch which will turnoff the burner if the temperature limit is reached is controlled by the two right connections (red dots).

Here the furnace limit switch is controlling a line-voltage device. The colored triangles refer to notes given below.

The illustration below shows the wiring for controlling line voltage when the jumper or pull out tab has been removed.

You can see that in effect the installer in effect is replacing the missing jumper by installing a connection to both terminals on either side of the contacts where the jumper was removed.

This important detail permits this control to be used to control line voltage (120V) devices even if the jumper has been removed or the paper pull-out tab on older controls has been lost.

Additional installation details for this control in the latest form are available from Honeywell (cited below).

To prepare the L4064B furnace control for use in a low-voltage application (typically 24VAC), simply remove the small red cardboard tab shown at left or break off the copper jumper between the two contacts in the same location on newer models of this control.

The brass jumper is the breakaway type. It must be removed when the limit is used in the low voltage circuit.

To remove jumper, break with a needlenose pliers and remove completely. Once removed, it is not replaceable.

If you make a mistake and remove this tab and then realize that you need to use this control to handle line voltage (120V or 240V) you can simply install a jumper wire as we show in the right-hand illustration just above on this page.

I installed a new fan limit switch but in my rush I missed removing the brass jumper for low voltage.

I tested it and it started and stopped. I can't seem to find the damage.

Do i need to buy and replace the limit switch again? I've checked the fuses and replaced both but still wont work. what else do I need to check. thanks

Dennis, I'm sorry to have to play it safe, but reading Honeywell's warning that the control could be damaged, I just wouldn't take a chance.

Watch out : A problem is that just as a bent spring can change how a switch performs, internal damage could be subtle and not visible, but the fan limit may not perform safely.

Certainly you can go through the recommended fan limit switch test procedures described above on this page to confirm that the swtich is doing what it is intended to do.

If you are still concerned I'd repalce the switch rather than take a chance or lose sleep over it.

The diagram at left shows how to wire the Honeywell L4064B combination furnace control when it is used to control low-voltage equipment.

This tab is found protruding from the control near the center of the bottom of its face. You'll see embossed on the control above this tab the words "Remove for Low Voltage".

Newer versions of this control have a brass jumper in the same location. The brass jumper is broken off for low-voltage use and is not replaceable once it has been removed.

The fan or furnace blower motor is controlled by the two left connections (green dots).

The furnace limit switch which will turnoff the burner if the temperature limit is reached is controlled by the two right connections (red dots). Here the furnace limit switch is controlling a low-voltage device such as a heating furnace gas valve. The colored triangles refer to notes given below.

Before wiring this or any control be sure to obtain the latest data from the manufacturer of the control and the furnace on which it is to be installed. Additional installation details for the Honeywell L4064B Combination Fan Limit control in the latest form are available from Honeywell.

After wiring this control make sure you've use the proper settings by reading over FAN LIMIT CONTROL SETTINGS and then be sure you test the combination fan and limit switch for safe and proper operation.

Excerpting from the 2017 document given below:

When installation is complete, disconnect the fan motor circuit at the L4064.

Turn on power and set thermostat to call for heat.

Burner should come on and limit controller should shut burner off when plenum temperature reaches the limit set point.

Turn off power, reconnect the fan switch, turn on power and again set thermostat to call for heat.

The fan should start when plenum temperature has reached fan-on setting.

The Honeywell L4068A,C,E,Ffan controls operate the furnace fan motor in response to plenum temperature in forced air heating systems.

L4068G attic fan control operates an attic ventilation fan in response to attic air temperature.

The L6068 air switch is used in downflow furnaces to prevent reverse air circulation and to provide protection against excessive temperatures caused by vlogged filters.

The 50A55-843 is an automatic gas interrupted ignition control that employs a microprocessor to continually monitor, analyze, and control the proper operation of the gas burner, inducer, and fan.

This fan and limit control combines, in one enclosure, a fan switch with an adjustable differential which operates the blower in a forced warm air furnace and a limit switch with a fixed differential which automatically shuts off the burner if the furnace temperature exceeds a predetermined high point.

A summer fan switch is incorporated in this control to provide a convenient method for manual operation of the fan for air circulation during the summer.

Cette commande de ventilateur et de limite combine, dans un seul boîtier, un interrupteur de ventilateur avec une différence réglable qui fait fonctionner le ventilateur dans un système à air pulsé et un interrupteur de limite à différence fixe pour arrêter la chaudière si sa température dépasse une température élevée spécifiée.

Watch out : To prevent electrical shock and/or equipment damage, disconnect electric power to system at main fuse or circuit breaker box until installation is complete. Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation.

Following installation or replacement, follow appliance manufacturers’ recommended installation/service instructions to insure proper operation.

Do not use on circuits exceeding specified voltages. Higher voltages will damage control and could cause shock or fire hazard. If in doubt about whether your wiring is millivolt, low or line voltage, have it inspected by a qualified heating and air conditioning contractor or a licensed electrician.

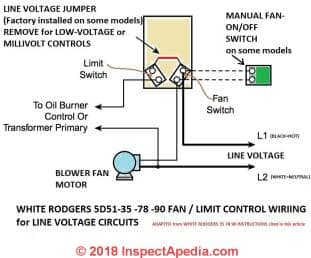

Above: Wiring diagram for the White Rodgers Fan Limit Control used at line voltage. [Click to enlarge any image] adapted from the White Rodgers 5D51 installation instructions cited here.

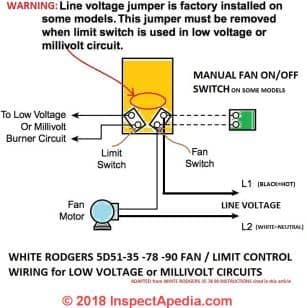

Below: Wiring diagram for the White Rodgers Fan Limit Control used with low voltage equipment. Note that the jumper is remoed for use with low voltage equipment, also adapted from the White Rodgers 5D51 installation instructions cited here.

Diagram for 5D51-35, -78, & -90 Installation Instructions at InspectApedia.com for low voltage equipment" />

Diagram for 5D51-35, -78, & -90 Installation Instructions at InspectApedia.com for low voltage equipment" />

Warning on Wiring Limit Controls and Switches in Reverse Polarity

Warning on Wiring Limit Controls and Switches in Reverse Polarity2018/10/01 John Ford said:

Line voltage is wired at the bottom left push-in terminal.

Load voltage (to the fan) is wired at the upper left push-in terminal.

What happens if these are reversed & will it ruin the limit control switch

Thanks for a critical question, John as we've all pushed a wire into the wrong connector from time to time.

Watch out : Warning about wiring fan limit switches or other controls in reversed polarity:

I don't know what specific fan limit switch you are using reverse wiring effects and I suspect that the risk of damage from wiring in reverse polarity is manufacturer and model-dependent as well as dependent on an additional detail I'll note. Here are some general remarks:

Most switches will "work" 'when wired in reverse polarity or "backwards" in that they turn-on or off the switched device as needed.

However wiring in reverse polarity can damage electrical components and can also be unsafe.

A review of THE BASICS of LIMIT SWITCHES [PDF] an excellent document on limit switches by Eaton, cited in detail below, reminds us that mis-wiring a switch as you asked can cause arcing when the switch operates; that arcing in turn can damage the switch or devices connected to it.

Polarity is a term which is used to describe the relationship between the load and line connections in a multicircuit switch.

Take a set of contacts with terminals that are made electrically common. If a line to line short circuit does not occur, these contacts are said to be connected to the same polarity.

If a line to line short circuit does occur the contacts are said to be of opposite polarity.

Some limit switches have their sets of contacts isolated from each other on the same pole. They are said to have electrically isolated outputs and are labeled as such.

Most devices, however, do not have isolated sets of contacts on the same pole and care must be taken to observe polarity.

Failure to do so can cause permanent damage to the switch, the wiring or both.

In some electronic devices leaving a live connection to the side of a circuit that's normally not energized can sometimes cause damage to a circuit or circuit board - a classic example is the effect of stray currents on the neutral wire in a circuit that damage an appliance or trip an AFCI.

When wired improperly the heating system is also unsafe. For example as you'll see in the Honeywell schematic I include below, if you reverse line and load wiring you are keeping the motor and other parts of the system always "energized" - that condition, combined with any of a number of errors or events, could shock someone.

Here is what Honeywell says, using the L4068A-series controller as an example

Connect the “hot” wire from the power supply to the upper left terminal. On L4068, connect the fan motor to the bottom terminal (marked LOAD); connect limit switch, if wired in the line voltage circuit, to the upper right terminal.

Note: excellent, comprehensive review of wide range of types of limit switches and their operation.

Excerpt from Introduction: Presence Sensing is the act of detecting the presence or absence of an object with a contact or non-contact sensing device.

The sensors then produce an electrical output signal that can be used to control equip-ment or processes.

Mechanical limit switches are contact sensing devices widely used for detecting the presence or position of objects in industrial applications.

The term limit switch is derived from the operation of the device it-self.

As an object (or target) makes contact with the operator of the switch, it eventually moves the actuator to the "limit" where the elec-trical contacts change state. Through this mechanical action, electrical contacts are either opened (in a normally closed circuit) or closed (in a normally open circuit).

Website: https://noraweb.org/contact/, educational module, retrieved 2018/10/01, original source: https://noraweb.org/wp-content/uploads/2016/10/NORA-Silver-Chapter-12.pdf

Website Excerpt:

. The National Oilheat Research Alliance, . was authorized by Congress in 2000 to provide funding that would allow the oilheating industry to provide more efficient and more reliable heat and hot water to the American Consumers. As a government sanctioned “check-off” program, $0.002 is collected at the wholesale level on every gallon of heating oil sold. While it is mandatory, the benefits greatly outweigh the minimal cost.

The four key arms of NORA are Consumer Education, Professional Education, improving energy efficiency and safety, and Research Consumer Education allows NORA to reach out to the consumer and show that oilheat is a clean, safe, efficient and modern form of heating.

This communication is essential to the industry’s survival.

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

On 2021-02-17 - by (mod) -

[Click to enlarge any image]

DG in addition to the example wiring diagrams found on this page, the IO manual for the Honeywell Fan Limit controller is given as a free PDF download - as well as manuals for wiring other limit switches.

On 2021-02-17 by Dgone

Where does the red wire go? No thermostat

On 2020-11-24 - by (mod) -

Thank you for the update that will perhaps help other readers as well. Keep me posted.

On 2020-11-24 by Richard Garcia

@danjoefriedman

Thanks for the reply. When you mentioned the manual it reminded me that the previous owner of my house (I've been living here one year) left her documents and I found the Carrier booklet for my model 58CMA oil furnace. Apparently I have an electronic fan timer (Honeywell circuit board ST9103) and the limit controls, two of them, are shown on the circuit diagram. Now I have to figure out the wiring for my new primary, but at least I'm not driving myself crazy trying to find a analog limit switch. Thanks again for your reply.

Richard

On 2020-11-23 - by (mod) -

Some forced-warm air furnaces use a snap switch or other control to manage the fan on-off-high limits, so you may not see the traditional Honeywell fan limit controller but you might see smaller, perhaps brown or black phenolic plastic "boxes" maybe just a couple of inches across. There ought to be one or more fan limit controls that will be mounted on or in the warm air supply plenum as that's where they have to sense temperature.

So you may be able to follow wires back from the blower motor to the plenum.

Tell me the furnace brand and model and if you don't already have the IO Manual that would show those details we may be able to provide one as we've got a zillion heater manuals as PDFs for readers to download.

On 2020-11-23 by Richard Garcia

Hello, I have a Beckett burner (AFG) forced air system that is about 20 years old. It works well. I just purchased a Honeywell primary R7284U to replace, if needed, the original R8184G just in case (it's 20 years old, too). The old primary has 3 wires and the new one is more complicated. My question: I cannot find the fan limit switch in my furnace. I've found two sensors at two places in the plenum but no fan limit switch. I looked in the lower and upper compartments and in front of the blower and found a Honeywell circuit board that a red wire from the sensors is plugged into, but no switch as shown in all the diagrams I have seen online. I need to wire the limit into the new primary when I eventually install it. I could use some help. A lot of it. Thank you very much. Richard.

On 2020-11-01 - by (mod) -

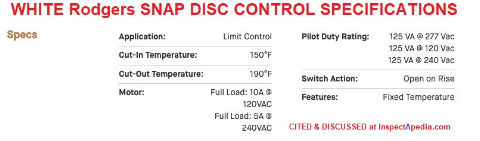

Thanks for the snap disc control wiring question, Gary.

Where a snap disc switch is simply opening or closing a circuit it's usually doing so by interrupting a single wire. In that case swapping the wires is likely to have no effect on the switch operation.

For example a switch that opens on temperature rise will simply interrupt a burner power circuit.

Watch out : it's not always the case that the wire connections make no difference on other controls or wiring connections: check the instructions that come with the specific control.

For example in some cases leaving power always present on the wrong side of some circuit boards can over time damage a board.

Another snap disc control example from Emerson is shown above. Notice that there's no identification distinction on the two wiring terminals.

On 2020-11-01 by Gary

What happens is you reverse the wires on a White Rodgers snap disc fan control?

On 2020-09-21 - by (mod) -

White Rogers offers this spec - note the voltages given [Click to enlarge any image]

On 2020-09-21 by Anonymous

Can you connect 120 volts to a 3L0 -190 white Rogers snap disc limit control

On 2020-01-18 by (mod) - how do you set the fan speed?

Many home heating furnace blower fans run only at one speed.

Some have a multi-speed fan that runs at different speeds under control of the circuit board in the air handler, depending on whether or not you are in heating or in cooling mode.

Some air handler circuit boards indeed include little dip switches or jumper pins that allow the service technician to set the fan speed(s) if the fan motor supports them.

for step by step instructions and for links to a number of air handler manuals with more instructions on setting the fan speed

Here is an example for York air handlers that explains the details of setting fan speed on the control board

Give me the brand and model of your air handler and I will look for its specific instructions.

On 2020-01-18 by jim

how do u control the speed of your fan

On 2019-05-04 by (mod) - when does the fan turn-on?

The fan comes on after the plenum is warmed. Not before - on a heating application.

Otherwise the unit would blow cold air on occupants.

Where to start: Watch the fan limit control to see if it's rotating to the FAN ON position.

On 2019-01-19 Joe T. - Carrier Day and Night FAU (Fan Air Unit)

I installed a new ICM 281 for a Carrier Day and Night FAU. When I turn on the power, the blower fan started running for 1-2 minutes, the hot surface igniter light up red hot, the burners ignited while the blower kept running. Everything seemed to work fine.

A few days later, the FAU stopped working. Shouldn't the surface igniter becomes red hot first, then the burners light and run for a few minutes, before the blower starts running to push the hot air up into the unit?

What should I test to see why the FAU stopped working?

Continue reading at FAN LIMIT SWITCH TROUBLESHOOTING or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see FAN LIMIT SWITCH INSTALLATION FAQs - questions & answers posted originally on this page

FAN LIMIT SWITCH INSTALLATION & WIRING at Inspect A pedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Share this articleOr use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Questions & answers or comments about how to hook up or wire the furnace blower fan limit control switch.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .